How fast can you drive with snow chains?

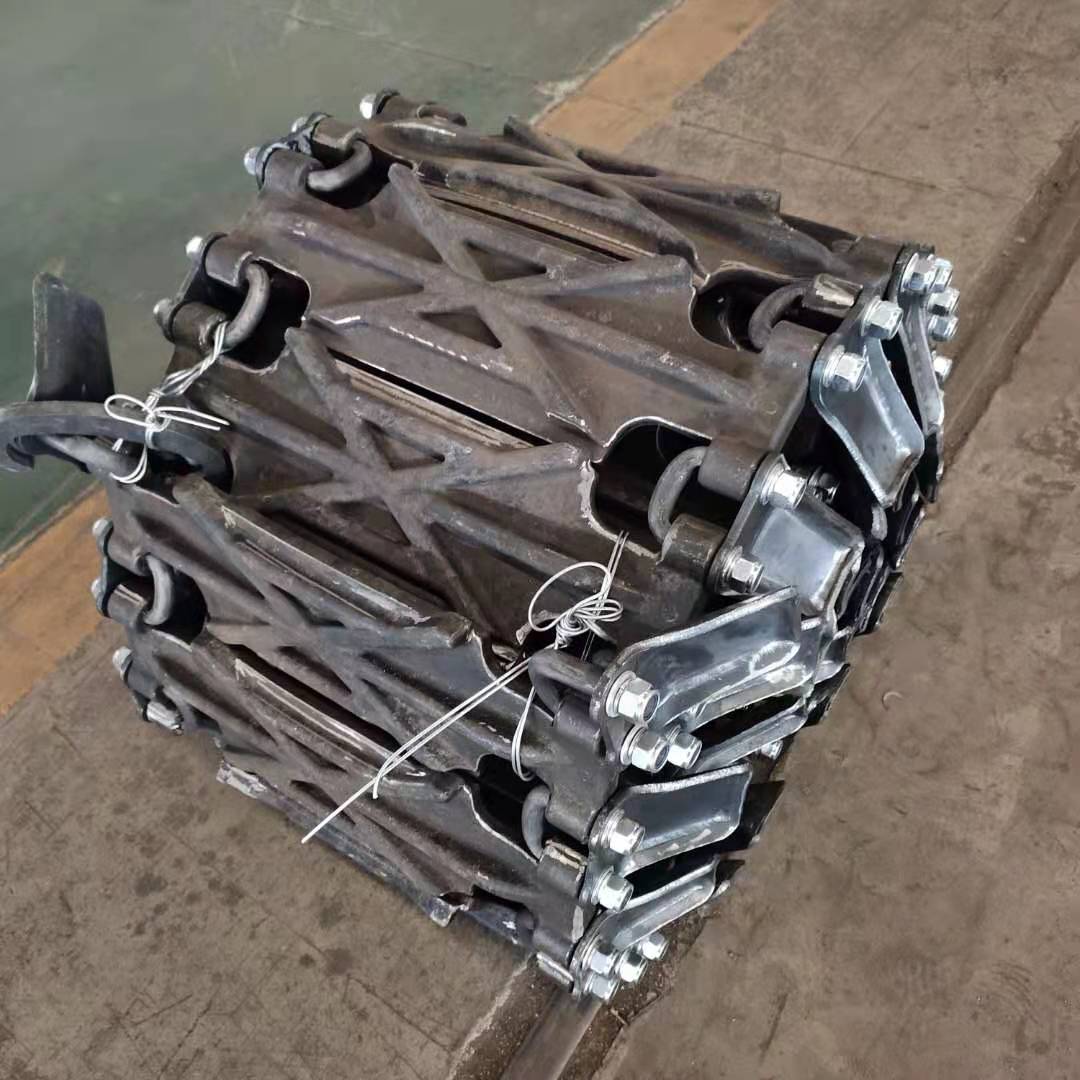

When it comes to driving with anti -scenery chains, including loader tire protection chainsThe maximum recommended speed is usually 30 km/h (48 miles/h). This speed restriction is applicable to most types of anti -scums and is critical of safety, especially in harsh winter conditions. Tireproof chains designed for heavy equipment meet similar requirements. Although these chains provide excellent clutch and protection, compliance with speed restrictions is extremely important to maintain their effectiveness and ensure the security of the operator in complex areas, such as quarries, mines and construction sites.

Maximum recommended speed

30 miles/h: Safe speed for most anti -scenery circuits

A speed limit of 30 km/h (48 mph) is a general guideline for driving with snow chains, including forklift snow chains. This speed is considered safe for most types of chains and vehicle sizes. It is important to understand that this limit is not arbitrary, but is based on extensive testing and real-world experience.

For heavy equipment such as forklifts, this speed limit is even more important. Tire protection chains are designed to operate in extreme conditions, but they are not completely safe. Driving at higher speeds can put unnecessary stress on the chains, which can lead to premature wear or failure.

Check the manufacturer's recommendations for specific limitations.

While 30 mph is a good rule of thumb, it's important to check your vehicle manufacturer's specific recommendations. forklift tire protection chains. Some chains may have lower speed indicators, especially those that are designed for especially difficult operating conditions or especially complex reliefs.

Manufacturers conduct careful tests to determine the optimal operating conditions of their products. These recommendations take into account factors such as chain material, its design and the proposed use. For example, for circuits designed for the mining industry, speed recommendations may differ from recommendations for chains designed for public work.

Lower speeds increase the service life of the chain and tires

Movement at low speeds when using the anti -scrap circuits, especially tire -protection circuits for loaders, can significantly extend the service life of both chains and tires. This is especially important in industries, where simple equipment can lead to significant costs.

Lower speeds reduce the shock load on the chains and tires, minimizing wear. This is especially useful in difficult conditions, such as quarries or mining enterprises, where the terrain of the terrain already has a significant load on the equipment. Supporting lower speeds, operators can guarantee that the loading tire chains will remain effective for a longer time, reducing the cost of maintenance and increasing the overall efficiency of work.

The speed must comply with road conditions

Reduce velocity on icy or snowy roads

When working with loaders or other heavy equipment on icy or snowy roads, it is extremely important to reduce the speed even below the recommended 30 miles/h (XNUMX km/h). In such conditions, the clutch with the road worsens significantly and the braking distance increases, even whenloader tire protection chainsinstalled.

On particularly slippery surfaces, it may be necessary to reduce speed to 10-15 km/h to maintain control. Remember that chains provide better traction, but do not make the car invulnerable to slippery roads. Drivers should always exercise caution and adjust speed depending on current road conditions.

Adjust for visibility and traffic conditions

Visibility is often reduced in winter, requiring a reduction in speed. Heavy snowfall, fog, or blizzard conditions can significantly limit a driver’s ability to see potential hazards. In these situations, it is essential to reduce speed to allow more time to react to obstacles or changing road conditions.

Traffic conditions also play a decisive role in determining the safe speed of work. In zones with mixed traffic, for example, on construction sites, where loaders can interact with smaller vehicles, it is important to maintain speed that ensures safe interaction with other equipment and vehicles. This is especially true when using the tire protection chains of loaders, since improved clutch can create a false sense of safety in operators.

Lower speeds improve adhesion and handling

Although the loader tire protection chains significantly improve clutch, work at lower speeds enhances this effect. Low speeds allow the chains to grind better with the surface, providing better handling and stability. This is especially important when moving along complex areas, such as steep slopes in quarries or uneven surfaces on construction sites.

Furthermore, lower speeds give operators more time to assess and react to changing terrain or unexpected obstacles. This increased reaction time is critical to maintaining control of heavy equipment, especially in adverse conditions where the consequences of losing control can be severe.

Risk of speeding

Chain damage or breakage at high speeds

Driving at excessive speed with forklift tire protection chains This can result in serious damage or even complete chain failure. The forces acting on chains increase exponentially with speed, placing enormous stress on the chain links and connection points. This is especially problematic on heavy equipment such as forklifts, where the machine's own weight amplifies these forces.

Ruping the chain at high speed can have catastrophic consequences. This not only makes the chains ineffective, but can also lead to damage to the tires of the loader, chassis or surrounding equipment. In the worst case, this can lead to loss of control, which can lead to accidents or injuries. Regular inspection of circuits for wear or damage is extremely important, especially if there are suspicions of speed.

Increased risk of accidents on slippery surfaces

Although the anti -scenes on the tires of loaders provide excellent clutch, they do not replace careful driving, especially at high speeds along the slippery surface. Improved clutch can sometimes create a false sense of safety, encouraging the operator to go faster than road conditions allow. However, even when using chains, sharp maneuvers or braking at high speed on an icy or snowy surface can lead to drift or loss of control.

In quarries and on construction sites, where the state of the surface can be unpredictable and change significantly at short distances, maintaining optimal speed is crucial. A section of the ice or an unexpectedly slippery place can be taken by surprise even the most experienced operators if they move too quickly. The consequences of an accident with the participation of heavy equipment can be serious, so speed control becomes a critical safety factor.

Potential damage to the vehicle due to weakened circuits

High speed can lead to a weakening or displacement of the loader tire protection circuits. Weakened circuits can be scrolling when rotating tires, which can lead to serious damage to the loader housing, hydraulic lines or other important components. Repair of such damage can be expensive and lead to long -term downtime of equipment, which affects the timing of the project and overall performance.

Additionally, loose chains can suddenly tighten or catch on obstacles, causing sudden jerks or stops. This not only poses a danger to the operator, but can also damage the forklift's transmission or suspension. Regularly checking chain tension becomes even more important if there is a risk of excessive speeding.