How to calculate the bucket capacity of a quarry excavator?

Calculating the bucket capacity of mining excavators is crucial for optimizing excavation productivity. This process involves considering factors such as bucket fill factor, material density, and matching the bucket size to the excavator's capabilities. Understanding these factors will help you determine the idealrock excavator bucketproductivity, ensuring efficient operation and maximising the potential of your equipment.

Bucket fill factors in mining

Bucket fill factors play a critical role in determining actual capacity.excavator bucketsThese factors determine the difference between a bucket's nominal capacity and the amount of material it can actually hold during operation. Let's delve into the intricacies of bucket fill factors and their impact on mining efficiency.

Analysis of bucket fill factors during stone excavation

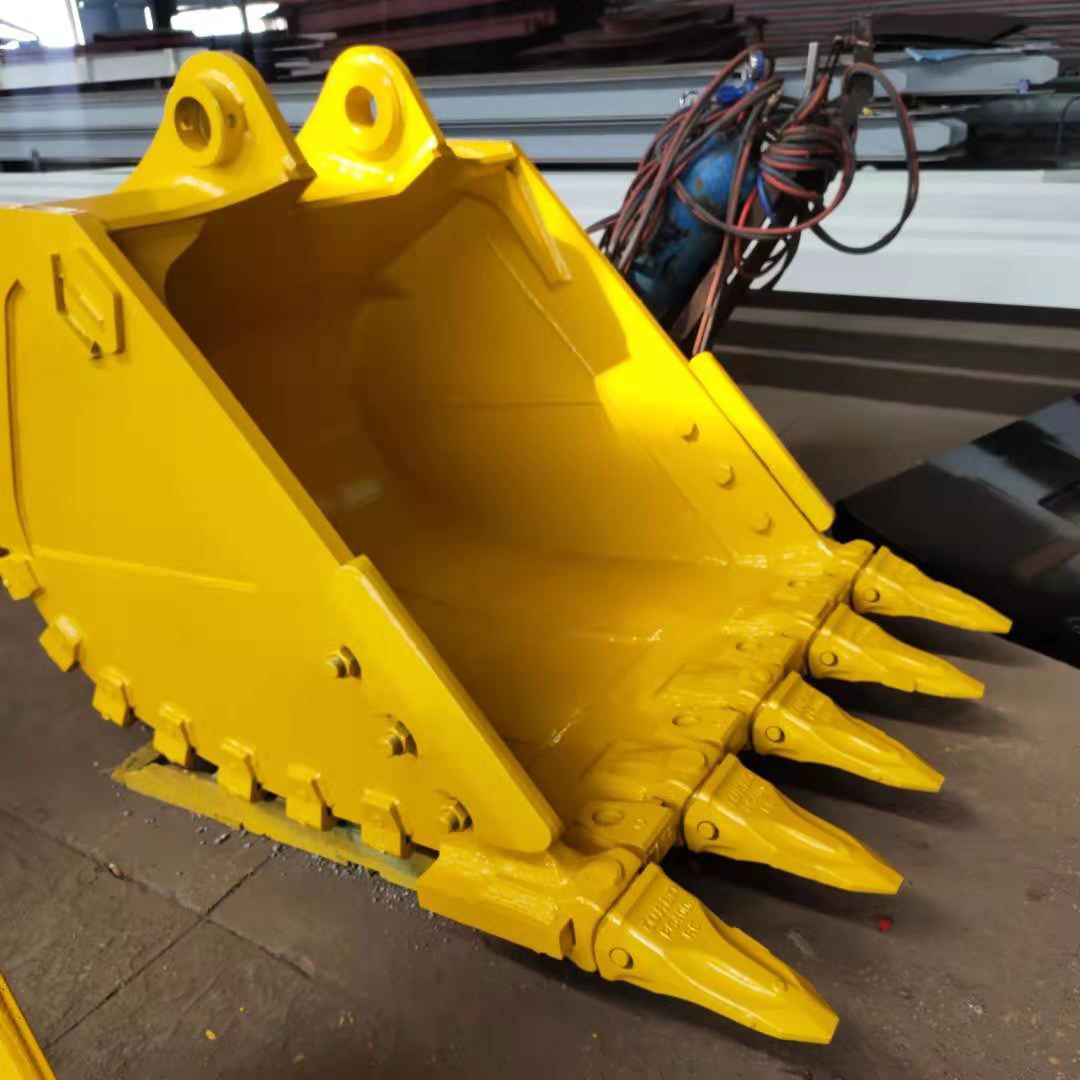

When excavating rock, the fill rate is typically between 60% and 95% depending on conditions. Hard, dense rock often provides a lower fill rate, while softer or crushed rock provides a higher fill percentage. To accurately analyze the fill factor, it is necessary to take into account rock fragmentation, its moisture content and bucket design. The configuration and spacing of the teeth has a significant impact on how well the bucket penetrates and retains material.

Influence of rock type on bucket filling efficiency

Different rock types have different characteristics that affect the efficiency of bucket filling. For example, granite and basalt, being hard and abrasive, can provide lower fill factors compared to softer sedimentary rocks such as limestone or sandstone. The angularity of the rock also plays a role: angular fragments tend to stick together, which can reduce the fill factor. Understanding these nuances helps to select the appropriate bucket design and estimate the actual capacity for specific geological conditions.

Optimizing duty cycles for improved performance

To improve productivity, focus on optimizing fill rates through strategic approaches. Implement proper blasting techniques to achieve perfect fragmentation, making it easier for the bucket to grab and hold the material. Regular maintenance of the bucket teeth and lips will ensure optimal penetration and prevent spillage. Additionally, train operators on proper loading techniques, such as turning the bucket at the right time to maximize filling. Fine-tuning these aspects will greatly improve excavator performance and overall project efficiency.

Material Density: A Key Variable in Performance Calculations

Material density is the cornerstone for accurate calculationsbucket capacity for mining excavatorsThe weight and volume of different types of rock directly affect the efficiency of loading and transporting material. Let's look at the critical aspects of material density and its role in load capacity calculations.

Measuring rock density to accurately estimate storage capacity

Accurately measuring the density of the rock in an excavator bucket is critical to accurately calculating productivity. Use laboratory tests or field measurements to determine the specific gravity of the rock being removed. For example, granite usually has a density of 2.6 to 2.7 g/cm³, and limestone - from 2.3 to 2.7 g/cm³. These values, combined with the bucket volume, provide a more accurate estimate of the weight of material that can be moved in one cycle. Remember that the in situ density is often different from the free density, so consider the swelling factor if necessary.

Adjustment of productivity calculations for different types of rocks

When there are different rock types within a single project, it is critical to adjust productivity calculations accordingly. Create a lookup table of common rock densities in your area for quick adjustments. For example, if you are switching from limestone to denser basalt, you will need to reconsider your expectations about how to load your excavator bucket. This proactive approach ensures accurate performance calculations throughout the project, preventing overload and potential equipment deformation.

Density Changes: Impact on Excavator Performance

Density changes have a significant impact on excavator performance and fuel efficiency. Heavier materials place more stress on the hydraulic system, which can result in longer cycle times. Closely monitor excavator performance when dealing with density changes. If you notice a decrease in efficiency, consider adjusting your digging strategy or downgrading to a smaller bucket to maintain the optimal balance between lifting capacity and machine capability. This adaptive approach helps maintain productivity while protecting equipment from excessive wear.

Optimizing Productivity: Selecting the Excavator Bucket Size

Achieving maximum productivity in mining operations depends on the synergy between your excavator and its bucket. The right combination ensures efficient material handling, reduced equipment wear, and optimized fuel consumption. Let's look at the key factors that influence choosing the ideal bucket size and maximizing your excavator's potential.

Choosing the Perfect Bucket Size for Your Excavator

Choosing the right size excavator rock bucket requires a careful balance of several factors. Start by checking your excavator's specifications to find out the recommended bucket capacity. Consider the typical density of the material being processed and the desired productivity. A bucket that is too large can overload the machine, while a bucket that is too small can reduce efficiency. For example, a 30-ton excavator can handle a bucket with a volume of 1.5 to 2.5 cubic meters, depending on the type of rock and job site conditions. Always consider your excavator's reach and dump height to ensure the bucket you select does not affect these critical parameters.

Balancing bucket capacity with excavator lifting capacity

Excavator lifting capacity is an important factor that is often overlooked when choosing excavator bucketsOverloading can cause instability, reduced efficiency and potential safety hazards. Analyze your excavator's lifting capacity graph at various boom positions and radii. Ensure that the fully loaded bucket weight (including material) does not exceed 80-90% of the machine's lifting capacity in the maximum extended position. This buffer ensures safe operation even in less than ideal conditions, such as uneven surfaces or unexpected changes in material properties.

Maximizing efficiency: choosing the right rock bucket size

Choosing the optimal excavator rock bucket size is all about finding the optimal solution that maximizes material moved per hour while minimizing wear and tear and fuel consumption. Consider cycle times carefully: a slightly smaller bucket that produces shorter cycles can outperform a larger bucket in overall performance. Analyze your job site's specific requirements, such as required bucket reach, typical bench height, and truck loading characteristics. Special bucket designs with optimized tooth spacing or special wear kits can further improve efficiency for your specific application. Remember that the goal— ensure stable and high performance without overloading the excavator.

Mastering the art of calculating bucket capacity for mining excavators is essential to optimizing your operations. By carefully considering bucket fill factors, material densities, and the critical match of bucket size to excavator capabilities, you can significantly improve productivity and efficiency. Remember, the key to success is constant evaluation and adjustment based on your site's specific conditions and material characteristics. With this knowledge, you'll be fully prepared to make informed decisions that will take your mining projects to the next level of success.