What materials are used to make excavators?

Modern excavation projects require shoring that can withstand enormous stresses while maintaining precision and reliability over long periods of time. The materials used in excavator manufacturing represent a complex combination of metallurgy, engineering expertise, and practical site requirements, which have changed significantly over the past decade.

Understanding the material composition of these important applications helps operators make informed decisions.equipment selection decisions, maintenance schedules, and operational expectations. Material selection directly impacts performance characteristics, durability, cost effectiveness, and the overall success of a project in a variety of applications, from forestry to urban demolition projects.

Today's excavator gripper technology includes three main categories of materials, each designed to meet specific performance requirements and operational challenges. These materials work synergistically to create fasteners that balance strength, flexibility and durability while maintaining the precision control required by modern excavation projects.

High strength low alloy steel (HSLA)

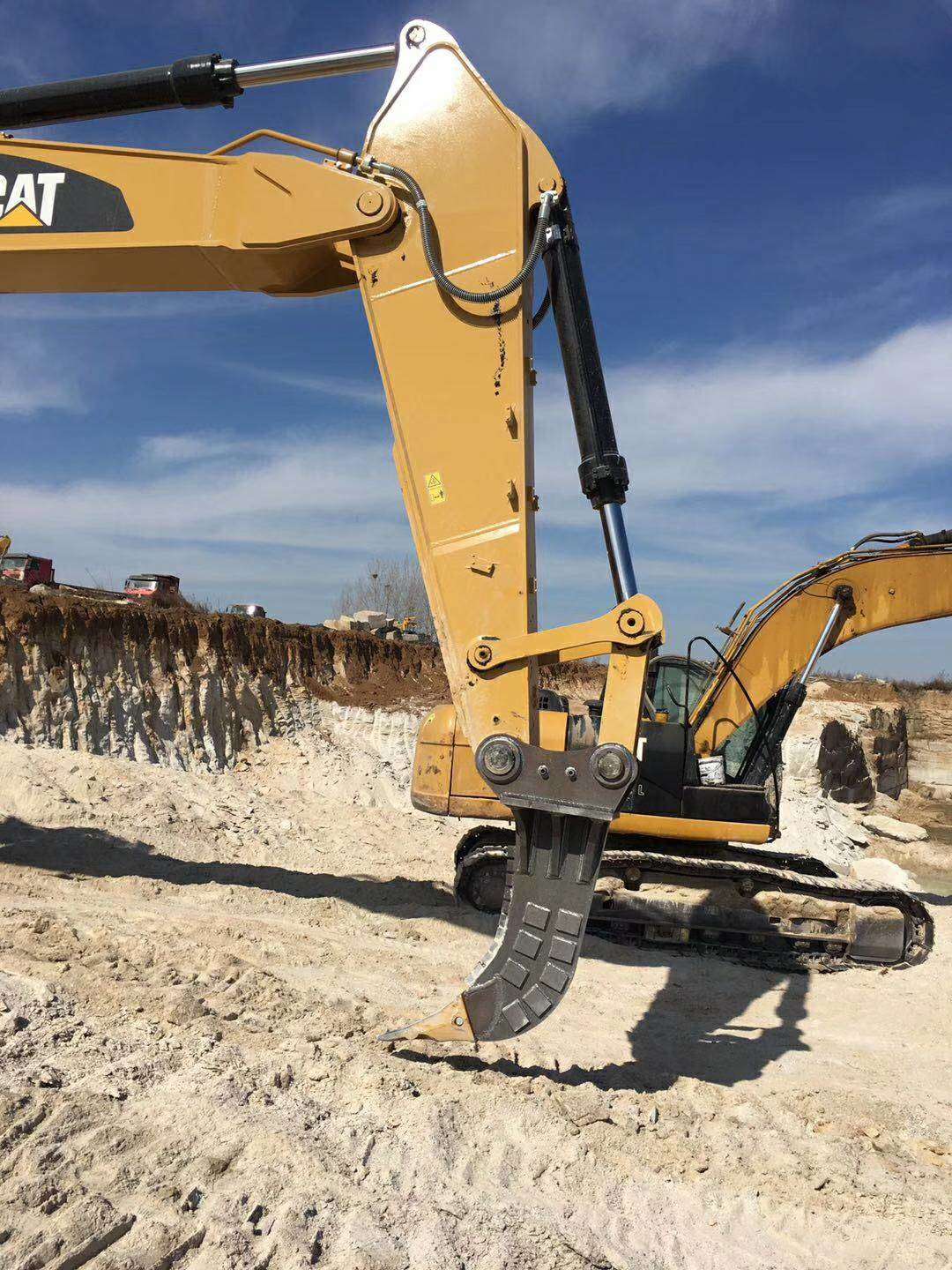

High-strength low-alloy steel serves as the fundamental material for the excavator root ripper design, offering an exceptional balance of mechanical properties making it ideal for demanding excavator applications. This advanced steel formula includes carefully controlled amounts of alloy elements that increase strength without compromising weldability or formability.

Metallurgical properties and composition

HSLA steel typically contains small percentages of elements such as niobium, vanadium, and titanium, which form microscopic precipitates that significantly strengthen the material's crystalline structure. These alloy additions allow manufacturers to achieve strengths exceeding 350 MPa while maintaining the excellent strength properties necessary for impact resistance.

Controlled carbon content, typically below 0.23%, ensures optimal weldability during manufacturing processes. This characteristic hascrucial forThe production of complex fastening geometries requiring multiple welded joints and reinforcing structures. The fine-grained structure of the material provides excellent fatigue resistance, extending service life under cyclic loading conditions.

Benefits of Structural Design

The improved strength-to-weight ratio of HSLA steel allows engineers to create more efficient structural designs without sacrificing performance. Thinner sections can support equivalent loads compared to conventional mild steel, reducing overall fastener weight and improving excavator fuel efficiency during operation.

Advanced forming methods utilize the excellent cold-forming properties of HSLA steel, allowing manufacturers to create complex curved sections that optimize stress distribution. These design capabilities result in fastenings that more effectively direct stress, reducing stress concentrations that can lead to premature failure.

Benefits of production and processing

The high weldability of HSLA steel allows manufacturers to use a variety of joining methods without compromising the material's properties. Reduced preheating requirements and reduced susceptibility to embrittlement in heat-affected zones simplify manufacturing processes while maintaining consistent quality standards.

The material's excellent machinability facilitates the precise manufacture of mounting interfaces, hydraulic connections, and control mechanisms. This characteristic is particularly valuable when creating fasteners that must perfectly interface with various excavator models and hydraulic systems.

Heat treatment processes can further improve the properties of HSLA steel for excavator grapples. Controlled cooling rates and heat treatment procedures allow manufacturers to optimize hardness, strength, and residual stress patterns to meet specific performance requirements.

Resistant steel plates

Resilient steel plates are a critical component of an excavator's grabber design, specifically designed to withstand the harsh, abrasive conditions encountered during excavation. These specialized materials protect key structural components while maintaining smooth operating surfaces that minimize energy consumption and maximize productivity.

Hardness classifications and applications

Modern wear plates are available in several hardness classifications, typically ranging from 400 to 600 HBW (Brinell hardness). The choice depends on the specific application requirements, with higher hardness levels providing superior abrasion resistance but potentially reducing impact resistance.

The microstructure of these inserts is characterized by martensitic or banitic phases, which provide exceptional resistance to scratching and cutting. Advanced manufacturing methods create a uniform hardness distribution throughout the entire insert thickness, ensuring consistent performance characteristics across the entire wear surface.

Specialized surface treatments, including plasma hardening and laser machining, can further enhance wear resistance in critical contact areas. These processes create extremely hard surface layers while maintaining the tough core properties, preventing catastrophic failures under severe impact conditions.

Strategic placement and design integration

Engineers are strategically placedwear-resistant platesIn high-contact areas, where material degradation occurs most rapidly. Common locations include the leading edges of chips, soil contact surfaces, and areas subject to sliding friction during operational cycles.

The design of an excavator grapple must account for differences in thermal expansion between the wear plates and the underlying structural materials. Proper joint design and fastening methods prevent stress concentrations that could compromise the integrity of both protective and structural components.

Replaceable wear plate systems allow operators to maintain optimal performance throughout the life of the fastener. These designs include standardized mounting interfaces that facilitate on-site replacement without the need for specialized tools or extensive disassembly procedures.

Production processes and quality control

The production of wear plates involves controlled cooling processes that ensure the desired microstructures without introducing harmful residual stresses. Water quenching, followed by precise burnishing cycles, creates the optimal balance of hardness and strength required for excavation applications.

Quality control procedures include comprehensive hardness testing, impact assessment, and dimensional inspection to ensure consistent performance characteristics. Non-destructive testing methods detect internal defects that could compromise operational reliability.

Advanced production facilities utilize automated systems that maintain precise temperature control throughout all heat treatment processes. These systems ensure repeatable results and minimize variations that could impact field performance or expected service life.

Hardened alloy steel for teeth/tips

Cutting teeth and excavator tips represent the most demanding application of materials technology in fastening design. These components must maintain sharp, sharp edges while withstanding enormous impact forces, abrasive wear, and the corrosive effects of soil chemistry. Selecting the appropriate hardened alloy steel is critical to maintaining operational efficiency and minimizing replacement costs.

Alloy composition and heat treatment

Premium dental materials typically include chromium, molybdenum and vanadium in carefully controlled proportions to achieve optimal combinations of hardness and strength. These alloy elements form stable carbides that resist wear while maintaining sufficient matrix strength to prevent brittle failure.

The heat treatment process involves austenitization at temperatures exceeding 850°C, followed by controlled quenching to achieve martensitic transformation. Subsequent hardening at moderate temperatures optimizes the balance of hardness and strength for specific soil conditions and operational requirements.

Advanced heat treatment techniques, including differential hardening, create teeth with extremely hardcutting edgesand gradually softer core areas. This gradient structure maximizes cutting efficiency while providing the strength needed to absorb impact energy without breaking.

Geometric design and performance optimization

Tooth geometry significantly impacts material performance and operational efficiency. Sharp angles maximize penetration but concentrate stress, while wider angles distribute loads more effectively but can reduce cutting efficiency. An optimal design balances these competing requirements based on expected soil conditions.

Surface treatments such as nitriding or carbonitriding create extremely hard surface layers that enhance wear resistance without compromising core strength. These methods typically increase surface hardness to 60-65 HRC while maintaining core hardness at around 45-50 HRC.

Self-sharpening designs incorporate specific angular relationships that maintain cutting efficiency throughout the wear process. As the material wears, the tooth profile naturally maintains optimal cutting geometry, extending service life and reducing maintenance needs.

Fastening and replacement systems

An excavator grab with teeth attached to the ripper structure requires careful consideration of differences in thermal expansion and stress concentration factors. Mechanical attachment systems must effectively distribute loads while allowing for thermal movement during work cycles.

Welded bonding methods require specialized procedures to prevent softening of the heat-exposed zone, which could compromise tooth performance. Preheating and controlled cooling processes maintain the material's properties while ensuring reliable bond integrity.

Replaceable tooth systems allow operators to maintain optimal cutting performance throughout the life of the fixture. Standardized mounting interfaces make field replacement easy while ensuring proper alignment and secure mounting under workloads.