Why are ballast cutters necessary for railway maintenance?

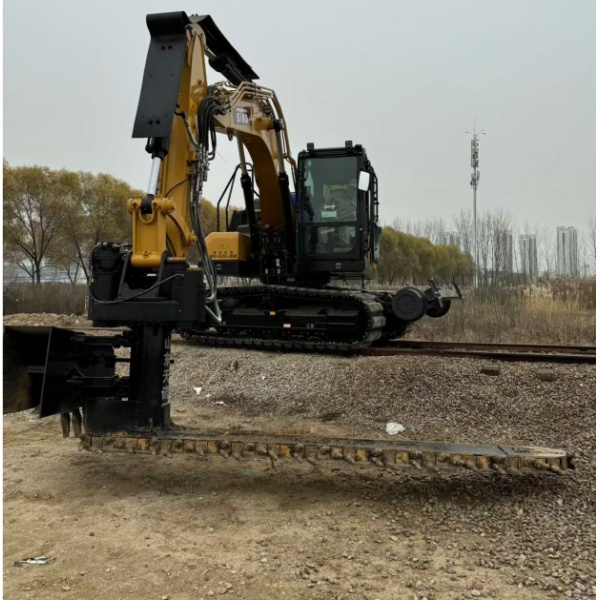

Railroad systems around the world depend on reliable maintenance practices to ensure safe and efficient operation. Among the most important equipment in this arsenal is the railway ballast shovel, a specialized machine that solves fundamental problems in rail maintenance. These powerful machines serve as the backbone of modern railroad maintenance programs, systematically removing contaminated ballast material from underneath railroads, cleaning it and restoring rails to optimal conditions.

Railway ballast is deterioratingover time due to constant stress from passing trains, exposure to weather, and contamination of surrounding soil and debris. When ballast is contaminated with fine particles and loses its angular properties, it turns from a stable foundation into a problematic substrate that undermines the integrity of the rail. This deterioration directly affects drainage capabilities, reduces load-bearing capacity and accelerates deterioration of railway infrastructure. Professional maintenance groups recognize that proactively addressing these issues through price reduction operations prevents costly emergency repairs and service failures while extending the life of railroad assets.

Maintaining track stability

Understanding ballast degradation and its impact

The stability of the railway track mainly depends on the mechanical propertiesrailway ballast, which provides the necessary support and load distribution for the railway infrastructure. During periods of operation, ballast materials undergo significant changes that undermine their effectiveness. Corner stones, which initially provide excellent interlocking characteristics, are gradually rounded as a result of constant mechanical stress and weathering processes.

This transformation creates cascading effects throughout the entire track structure. When ballast loses its coal content, the interlocking mechanism between individual stones is significantly weakened. Fine particles, commonly referred to as "fines", accumulate in the ballast matrix, creating a concrete-like consistency that prevents proper drainage and reduces the ballast's ability to effectively distribute loads across the rail foundation.

The Role of Demolition in Restoring Structural Integrity

Professional demolitions address these fundamental stability issues through systematic ballast renewal. A railway ballast shovel removes contaminated material from critical areas under the rail structure, typically reaching depths of up to 800mm depending on specific maintenance requirements and rail conditions.

This process restores the necessary mechanical properties to ensure track stability. Fresh corner ballast provides superior load distribution capabilities, effectively transferring forces from passing trains to the base of the rail. Restoring proper ballast performance significantly reduces trace reinforcement and geometric deviations that would otherwise require frequent corrective maintenance activities.

Long-term stability benefits

Railroad operators that implement comprehensive reduction programs experience measurable improvements in rail performance.Properly supported ballast sectionsexhibit increased resistance to lateral movement, reduced vertical settlement rates, and improved overall geometric stability over long periods of service.

These stability improvements directly translate into operational benefits, including reduced service frequency, improved ride quality for passengers and cargo, and improved safety margins for high-speed operations. Investments in systematic price reduction operations provide significant returns through lower life cycle costs and improved asset utilization.

Increased drainage efficiency

The critical importance of effective route drainage

Water management is one of the most challenging aspects of railroad maintenance, directly impacting track stability, long component life, and operational safety. Effective drainage systems prevent water from accumulating in the road structure, which can lead to ballast contamination, weakening of the riser, and accelerated deterioration of road components.

When ballast is contaminated with fine particles, its permeability decreases dramatically. Water trapped in the rail structure creates hydrostatic pressure, which destabilizes the ballast matrix and promotes pumping conditions as the train passes. These conditions accelerate ballast degradation and create maintenance problems that get worse over time without proper intervention.

The role of pruning in restoring drainage

Ballast trimming operations specifically target drainage problems by removing impervious contaminated material and replacing it with clean, well-graded ballast that facilitates proper water flow. Systematic removal of contaminated ballast removes a major barrier to effective drainage, restoring the rail structure's ability to effectively manage water.

Modern backhoe systems with rail ballast trimmers include screening capabilities that separate reusable ballast from fine contamination. This approach maximizes material utilization while ensuring that only clean, properly graded ballast is returned to the rail structure. The result is an updated drainage system that effectively manages water flow and prevents future pollution cycles.

Preventing waterway problems

Proper drainage maintenance through cutting operations prevents numerous water related problems that can seriously affectrailway operation. These include ballast pump, sub-class instability and accelerated corrosion of steel components. By maintaining optimal drainage characteristics, railway operators avoid costly emergency repairs and service disruptions associated with water-damaged sections of the railway.

Increased drainage efficiency also improves route geometry stability in adverse weather conditions. Routes with properly functioning drainage systems maintain their geometric integrity during heavy precipitation and freeze-thaw cycles, reducing the need for emergency maintenance and ensuring consistent operational reliability.

Extending the life of the track

A comprehensive strategy for extending the life of assets

The railway infrastructure isRepresent significant capital investments that require strategic approaches to maintenance to maximize service life and return on investment. Ballast cutting operations serve as the cornerstone of comprehensive asset management strategies that address the multiple degradation mechanisms that limit the lifespan of a highway.

Systematic ballast renewal through re-cutting operations addresses the root causes of road deterioration rather than simply treating the symptoms. This proactive approach prevents minor maintenance issues from developing into major structural problems requiring extensive restoration efforts and significant capital expenditures.

Preventing premature replacement of components

Well-maintained ballast significantly reduces stress concentrations on rail components, extending the life of rails, braces and fastening systems. When ballast provides proper support and load distribution, rail components operate within their design parameters, experiencing reduced fatigue stress and wear rates.

Professional maintenance teams using advanced railway ballast shovel technology can selectively address problem areas while keeping sections in good condition. This targeted approach optimizes maintenance resources and prevents unnecessary disruption to stable sections of the roadway, which contributes to the overall longevity of the system.

Economic benefits of proactive maintenance

Railroad operators that implement systematic price reduction programs realize significant economic benefits by extending asset life cycles and reducing emergency maintenance requirements. Proactive ballast maintenance costs significantly less than reactive approaches that address problems after they have caused operational or component failures.

Investment in regular recutting operations provides measurable returns through shorter rail replacement cycles, reduced maintenance material consumption and improved operational reliability. These benefits compound over time, creating significant cost savings that justify the initial investment in specialized equipment maintenance and operating programs.