How does a clam bucket work?

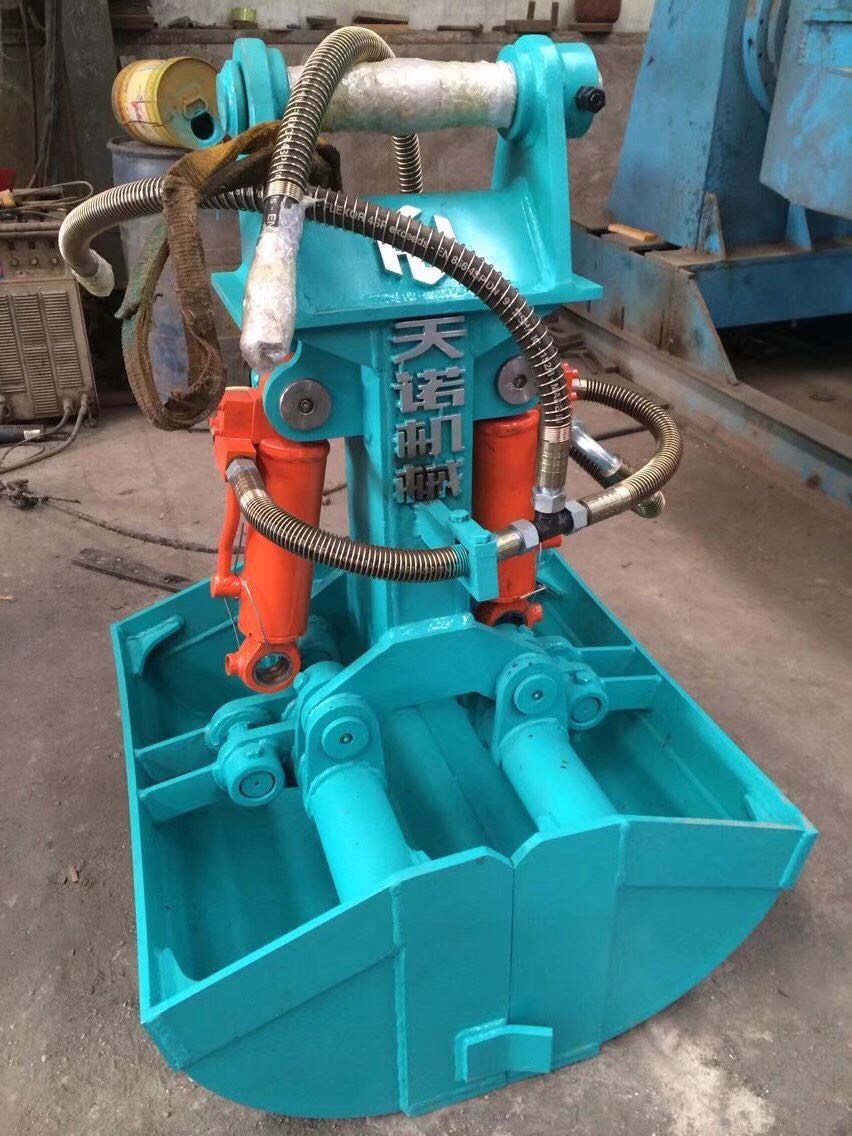

The terminal bucket works through a complex hydraulic system, which allows you to accurately capture and raise operations in various construction media. The mechanism uses two symmetrical shells connected by hinges that open and close like a grinder. When hydraulic pressure is used, the cylinders are activated, which leads to the opening of a bucket to collect the material. When this pressure is released, the sink is tightly closed around materials such as soil, gravel or garbage. This specialized mount differs in limited spaces, where traditional excavations are complicated, which makes it invaluable for deep trenches, processing materials in ports and accurate excavation tasks. Operational efficiencyThe buckets are dueIts ability to combine vertical lifting force with a horizontal capture, which allows operators to achieve exceptional accuracy even when working with free materials or in water conditions.

Energy source

Integration of the hydraulic system

Primary power for buckets with a shellIt comes from the hydraulic system of the excavator. This integration allows you to work freely without the need for additional energy sources. The hydraulic pump of the excavator generates a liquid under pressure, which flows through the hoses and valves to the bucket cylinders. This hydraulic fluid under pressure creates the necessary strength to open and close the bucket shells.

The hydraulic system usually works at a pressure of 3,000 to 5000 psi, depending on the excavator model and the size of the bucket. This high -pressure liquid passes through reinforced hoses designed to withstand the difficult conditions of the construction environment. Hydraulic schemes include safety valves that prevent the system overload, providing consistent operation even under various load conditions.

Management mechanisms

Operators control a bucket from Molluska through special levers or joysticks in the cabin of an excavator. Modern excavators are equipped with electronic proportional control devices, which allow you to accurately modulate a hydraulic flow. This accuracy allows the operators to adjust the opening width and the closing force based on the processed material.

The control system includes several sensors that control hydraulic pressure, temperature and flow rate. These sensors submit data to the excavator onboard computer, which optimizes performance and prevents damage to hydraulic components. Some advanced models include memory functions that allow operators to pre -configure the general opening width for repeating tasks, increasing performance.

Energy distribution

The distribution of power in the bucket system with a scolopus includes the direction of hydraulic pressure to various cylinders based on the desired action. The excavator hydraulic collector contains directed control valves that direct the liquid under pressure to the corresponding cylinders. When the bucket is opened, hydraulic pressure proceeds to the side of the cylinder advancement; When closed, the pressure is redirected to the side of the retreat.

This power distribution system includes flow control valves that regulate the speed of the cylinder. By adjusting these valves, operators can increase or reduce the speed of opening and closing the bucket without affecting the capture force. The system also includes pressure compensators that support consistent work regardless of the weight of the load or resistance that is faced with during operation.

Opening and closing action

The function of the hydraulic cylinder

Opening and closing mechanismBuckets with MolluskaIt is relied on on hydraulic cylinders, strategically located between the two halves of the bucket. These cylinders consist of a piston rod that stretches or defends in a hermetic chamber. When the hydraulic fluid enters the cylinder chamber behind the piston, it makes the piston forward, stretching the rod and opening the bucket shells. On the contrary, when the liquid enters the opposite camera, the piston retreats, pulling the shell together for closing.

Most structures use double cylinders installed in parallel to ensure a balanced distribution of force on the shells of the bucket. This two -cylinder configuration prevents twisting or uneven closure, which can jeopardize capture efficiency. The cylinders are equipped with chrome bonds and specialized seals that resist the pollution of dust, dirt and moisture common in the construction conditions. Piston protective devices protect vital components from damage by blow during operation.

Mechanical connection system

The system of mechanical connection converts the linear movement of hydraulic cylinders into a rotating movement necessary for the work of a bucket. This system usually consists of rotary points, a hinge and connecting hands, which effectively transmit power while maintaining constructive integrity. The geometry of the connection is carefully designed to optimize the angle of opening the bucket and closing force in all its working range.

The key components of this system include fixed steel pin at the rotary points, shoes that reduce friction, and reinforced connection points, which evenly distribute the voltage according to the structure of the bucket. The connection system allows the maximum opening width of approximately 45-60 inches, depending on the model, while maintaining constructive stability under the load. Regular lubrication of these mechanical components provides smooth operation and extends the service life in difficult conditions.

Synchronization mechanisms

Proper synchronization between the two shells of the bucket ensures uniform closure and optimal maintenance of the material. This synchronization occurs through mechanical joints, which connect both shells with the central rotary point. As hydraulic pressure activates the cylinders, both shells move at the same speeds, maintaining alignment throughout the work cycle.

The improved buckets with a scolopus include valves that regulate the hydraulic flow to each cylinder, compensating for any potential imbalance caused by uneven load or resistance. Some models are equipped with electronic synchronization systems that use the position sensors to monitor the alignment of the shell and automatically adjust hydraulic pressure to maintain perfect synchronization. This technology is especially valuable when handling irregular materials or working in difficult underwater conditions.

Capture and rise

Material participation

The effectiveness of a bucket with a mollusk largely depends on its ability to interact with the material. The bucket frames have specially designed edges that penetrate the materials for safe capture. These edges vary depending on the intended use - gear edges for rocky materials, straight edges for sand and thinner particles or reinforced edges for tolerable work. The design of the shell creates the optimal distribution of pressure according to the captured material, preventing spills inRise time.

The inner surface of the shells often includes wear -resistant linings, which extend the life of the bucket when handling abrasive materials. Some specialized models are equipped with perforated shells that allow you to drain water when working with flooded materials, significantly reducing unnecessary weight during lifting operations. The geometry of the shell creates a compression area, which reliably holds the materials even with the exposure of vibrations and movements, conventional during operation of the excavator.

Load management

Buckets with sluts should effectively control various loads of load while maintaining operational stability. The cargo is usually varied from 0.2 to 2.0 cubic meters, depending on the model and compatibility of the size of the excavator. The distribution of weight according to the design of the bucket plays a decisive role in preventing the concentration of stress, which can lead to a structural failure.

Built -in valves of pressure softening in the hydraulic system prevent overload, automatically freeing excess pressure when the bucket encounters resistance exceeding its structural power. The technology of loading loads in advanced models controls the weight and controls hydraulic pressure accordingly, optimizing energy efficiency when extending the component service life. The center of gravity of the bucket shifts during operation, requiring complex stabilization systems that compensate for these changes to maintain the balance of the excavator.

Features of accurate management

Modern buckets with Molluska include many functions that increase operational accuracy. Proportional hydraulic control allows operators to modulate the closing force based on the characteristics of the material, applying greater pressure for dense materials and reducing pressure for fragile objects. This ability of alternating pressure is invaluable in tolerable work, where selective seizure of the material is required.

The position sensors set at key points provide real -time feedback on the position of the bucket shell, which allows you to accurately position in a millimeter when working in limited spaces. Some advanced models are equipped with programmable stop points, which allow operators to pre -configure the position of partial opening for specialized tasks. Rotation mechanisms allow a 360 -degree bucket to rotate, eliminating the need to move the entire excavator when working in narrow spaces or performing complex tasks for processing materials.