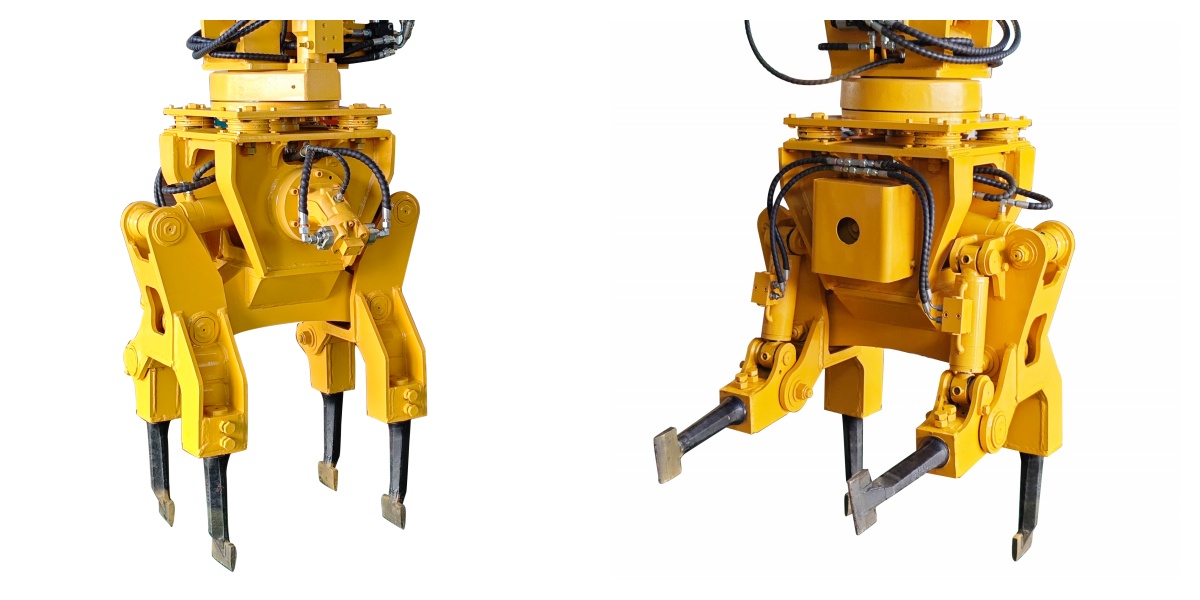

Railway switch ballast manipulation

Railway switchThis specialized machine is designed for efficient and precise blasting operations on railways (switches and crossings). Its compact design and powerful vibration system ensure uniform compaction of ballast under the tracks, ensuring stable track geometry and extending the track's service life.

Railway switchThis specialized machine is designed for efficient and precise blasting operations on railways (switches and crossings). Its compact design and powerful vibration system ensure uniform compaction of ballast under the tracks, ensuring stable track geometry and extending the track's service life.

Specification

| Item/Model | TNDCDGJ75 | TNDCDGJ150 |

| Applicable tonnage (ton) | 7-10 | 13-18 |

| Applicable track width (mm) | 1000/1435/1520 | 1000/1435/1520 |

| Vibration frequency (Hz) | 30 | 40 |

| Number of tamping heads (pcs.) | 4 | 4 |

| Rotation angle | 360 | 360 |

| Outrigger inclination angle | 85 | 85 |

| Outrigger tilt height (mm) | 470 | 470 |

| Maximum compaction depth (mm) | 400 | 400 |

| Clamping range (mm) | 375-625 | 375-625 |

| Maximum engine speed (rpm) | 5600 | 5000 |

| Engine displacement (ml/rev) | 45.6 | 56 |

| Weight | 980 | 1200 |

| Size | 850 * 1020 * 1850 | 950 * 1180 * 1890 |

Key Features

1.Compact design for switch areas

Specially designed for railroad bends and crossings, the removal unit has a narrow frame and flexible arm structure, allowing it to easily work between rails, frogs and switch components where large removals cannot reach.

2.Precision control through excavator boom

The master is designed for excavator mounting, using a boom to control lifting, rotation, and positioning. This allows for precise blasting of complex switch geometry with minimal manual effort.

3. Reinforced rebounds

Each impact peak is produced by a hammer process, ensuring superior impact resistance and long service life even under continuous heavy vibration.

4. Improved track stability

The machine uses a high-torque motor, providing precise compaction of the ballast under the pads, effectively restoring track geometry and improving long-term stability, especially in corners and junctions where dynamic loads are higher.

Applications

Railway maintenance: routine maintenance of high-speed and freight railways.

Transit systems: stabilization of metro, light rail and tramway.

Construction projects: post-reopening of new tracks or upgraded sections.

Mining and industrial railway: heavy-duty applications in harsh conditions.

Frequently Asked Questions

Q1:How often should equipment maintenance be performed?

A1: Regular maintenance is recommended every 500 operating hours, including hydraulic system inspection, lubrication, and wear parts inspection. Tiannuo provides comprehensive maintenance manuals and support.

Q2:Can the product be customized?

A2: Yes, we offer customization to meet the specific requirements of your rail maintenance projects. Contact us to discuss your needs.

Q3:What is the delivery time for the product?

A3: Our standard delivery time is 6-8 weeks, depending on the level of customization required.